Finding an Possible Alternative: A Comprehensive and Collaborative Approach

The tire industry has created a 36-member consortium to transparently and collaboratively work with regulators, partners and interested stakeholders to identify a potential alternative to 6PPD that is protective of motorist safety and the environment.

6PPD: An Essential Ingredient for Tire Safety

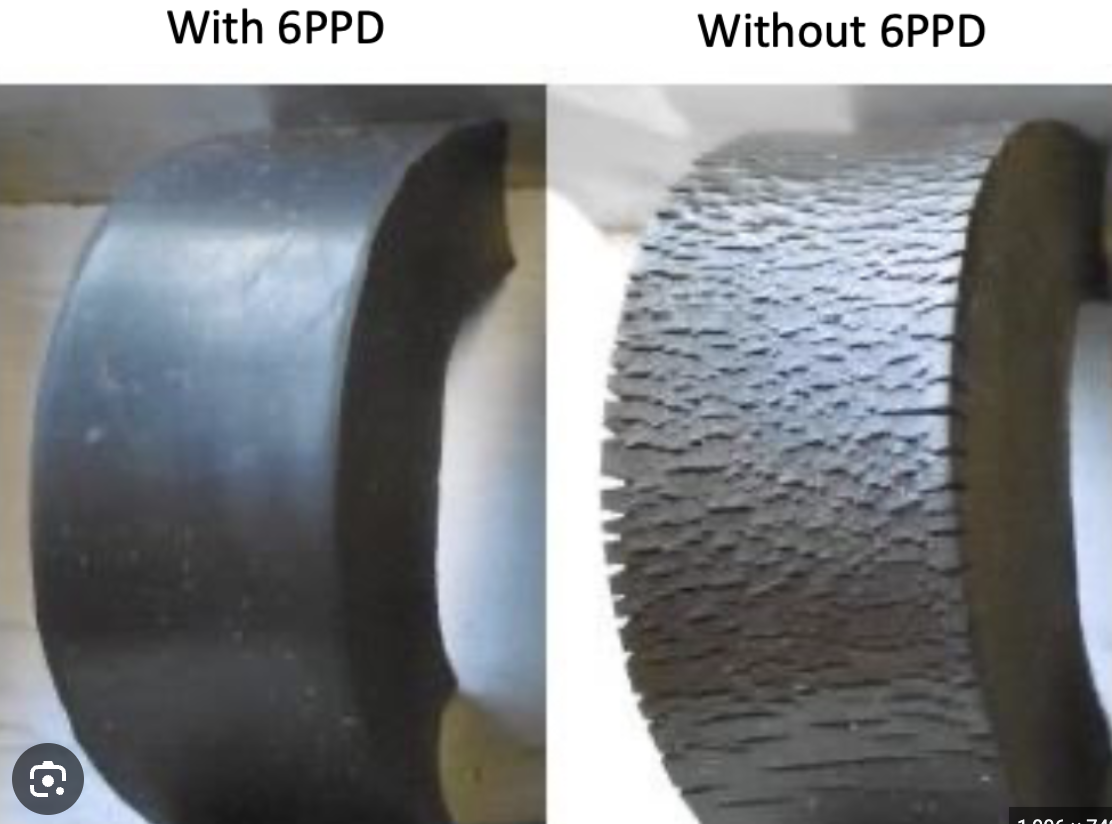

Safety is at the core of everything tire manufacturers do and the complex blend of rubber compounds and materials in our products is designed to withstand a wide range of demanding conditions. 6PPD serves an essential safety function in tires as an antioxidant and antiozonant, protecting the components of the tire from attack by ozone, oxygen, and other factors. Without 6PPD, a tire’s integrity would be severely and quickly compromised, jeopardizing driver and passenger safety. Any potential alternative identified to replace 6PPD must continue to ensure compliance with Federal Motor Vehicle Safety Standards (FMVSS) and other consumer, vehicle, and tire manufacturer requirements.

6PPD is currently used in all USTMA member passenger, light truck, truck and bus radial, and motorcycle tires. USTMA is not aware of any new motor vehicle tires available today that do not contain 6PPD.

6PPD vs. 6PPD-quinone

6PPD-quinone, or 6PPDQ, is a recently discovered transformation product of 6PPD that may form when 6PPD reacts with oxygen or ozone under certain conditions. 6PPDQ is not used in U.S. tire manufacturing. Today there is no commercially available alternative to 6PPD that both provides comparable safety and performance in motor vehicle tires and minimizes potential environmental effects.

USTMA Proactively Seeks to Identify Possible Alternatives to 6PPD

6PPDQ Identified | USTMA requests DTSC review 6PPD in tires

6PPD-quinone was identified, USTMA requests the California Department of Toxic Substances Control (DTSC) prioritize a review of 6PPD in tires

USTMA Creates 6PPD Consortium

USTMA mobilizes a consortium of 16 tire manufacturers to conduct an alternatives analysis for 6PPDin tires after a decision by DTSC to act on USTMA’s recommendation to list 6PPD in tires as a Priority Product under the state’s Safer Consumer Products (SCP) program.

6PPD Designated Priority Product | USTMA Expands Consoritium Work

DTSC designates 6PPD in tires as a Priority Product and USTMA expands its consortium to 36 tire manufacturers from around the world to prepare a Preliminary (Stage 1) Alternatives Analysis (AA) to identify and evaluate potential alternatives to 6PPD in tires.

DTSC Compliance Reporting Deadline

Individual consortium members submitted the report to DTSC to meet compliance deadline.

USTMA Submits Updated Report to DTSC

USTMA submits an updated report in response to DTSC comments.

DTSC Accepts Consortium Stage 1 AA Report

6PPD Alternatives Analysis Consortium receives Notice of Compliance from DTSC for its Stage 1 Alternatives Analysis report

Consortium Progress Report Due to DTSC

Consortium’s Stage 2 AA report Due to DTSC

6PPD Alternatives Analysis Work

Stage 1: Consortium Identifies Seven Possible Alternatives After Extensive Review

The Consortium is actively working to identify possible alternatives that warrant further review of their potential impact to sensitive aquatic species. In support of this work, USTMA has initiated a joint research project with the U.S. Geological Survey to assess and refine methods of evaluating potential alternatives to 6PPD for use in tires.

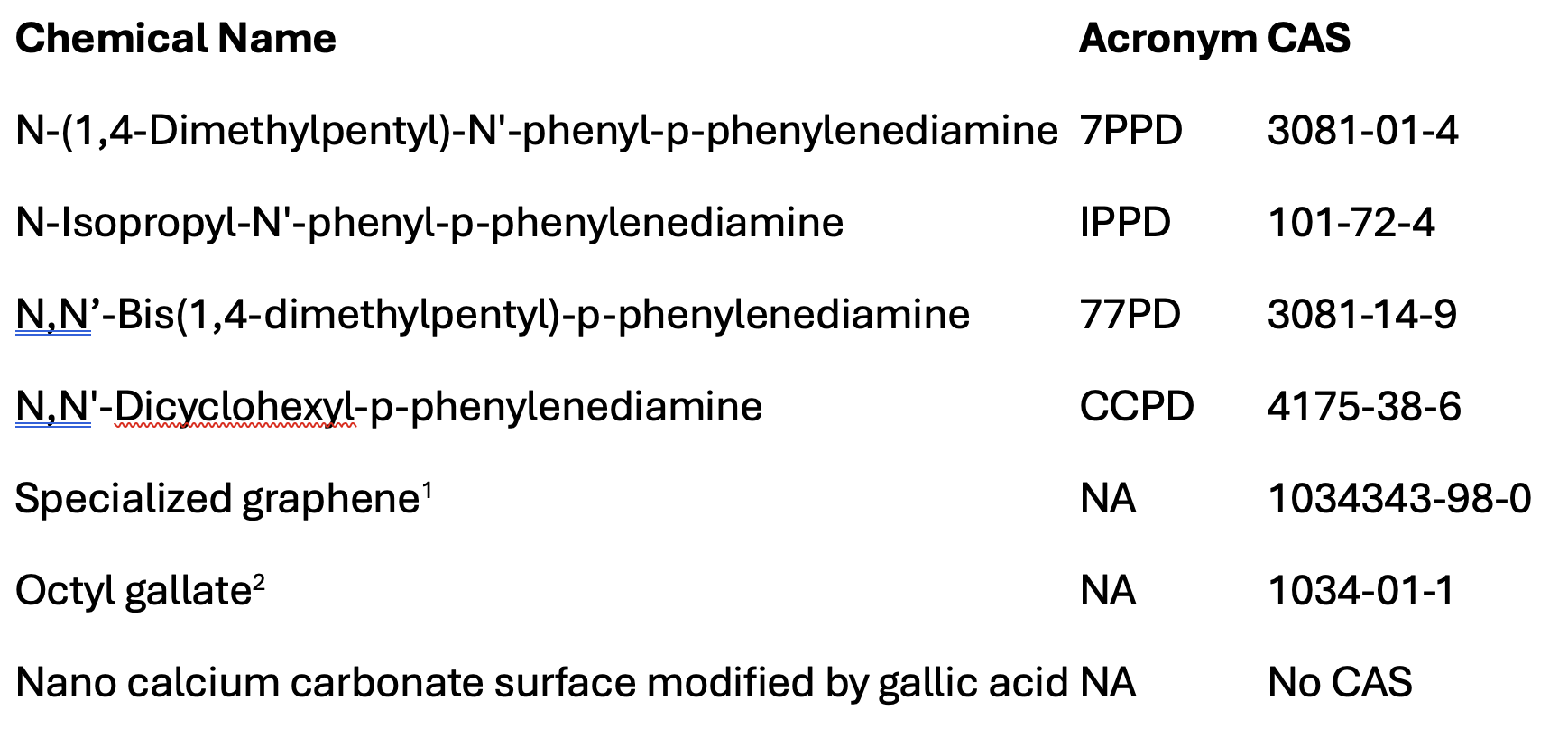

In total, more than 60 initial candidate alternatives were identified for screening and scoring for suitability as possible alternatives to 6PPD in tires. In the Stage 1 AA Report, the Consortium considered different types of alternatives to 6PPD as an antidegradant in tires, including: (1) other phenylene diamines (“PPDs”) that are the most logical and possibly most straight-forward alternatives to 6PPD, and (2) non-PPD possible alternatives that likely pose greater challenges to incorporating into tire chemistry.

Forty of the more than 60 initial candidates were subjected to an extensive review, which identified seven possible alternatives that warrant further evaluation in the Stage 2 AA. Of those seven possible alternatives, four are other PPD compounds, while three are non-PPD materials.

Below is a list of the possible alternatives identified:

Stage 2: Consortium Continues Work to Identifying Possible Alternative to 6PPD in Tires

On August 26, 2024, members of the Consortium's received a Notice of Compliance from DTSC for its Stage 1 AA report. The notice will allow the Consortium to formally launch development of a Stage 2 AA report. At the end of the Stage 2 AA, USTMA is optimistic that one or more possible alternatives that hold promise to replace or materially reduce 6PPD in motor vehicle tires will be identified, subject to further safety and performance testing. The Consortium’s Stage 2 report is due to DTSC on August 19, 2026, with an annual progress report due on August 19, 2025.

Initial candidate alternatives

Alternatives evaluated in extensive review

Alternatives advanced to Stage 2 AA

Supporting Research and Filling Data Gaps

The tire manufacturing industry’s effort to identify potential alternatives to 6PPD includes important work with regulators, researchers and other industry partners.

USTMA’s collaboration with Washington State Department of Ecology dates back to 2019, predating the identification of 6PPDQ, and includes providing information on tire materials that may be found in stormwater discharge, providing technical expertise on identifying and researching tire and road wear particles (TRWP) and providing samples of cryogenically-milled tire tread (CMTT) to support research on TRWP.

USTMA plans to work with U.S. Environmental Protection Agency (EPA) officials as they continue their evaluations of 6PPD under the Toxic Substances Control Act (TSCA) and as appropriate in other areas of focus for the Agency, including research and stormwater management.

USTMA has been working closely with the Interstate Technology and Regulatory Council (“ITRC”), which includes many of the same officials working at the state and federal levels, tribes, NGOs and other stakeholders as part of the ITRC’s project on tire anti-degradants.

In addition, as part of the Alternatives Analysis, USTMA signed a Cooperative Research and Development Agreement (“CRADA”) with the U.S. Geological Survey (“USGS”) to test potential alternatives against coho salmon cell lines. USTMA is also working with our global partners to assess relevant data gaps.

Comprehensive Approach: Research and Mitigation

While efforts to find and implement a potential alternative to 6PPD (while still complying with safety standards) will take time, there is work that can be done now to reduce 6PPD and 6PPDQ in the environment. These measures include street sweeping in urban areas, choosing pavement surfaces (such as rubber modified asphalt and permeable pavement) that reduce tire abrasion and mitigate stormwater impacts, installing bioretention technologies to treat stormwater and maintaining proper tire inflation to reduce tire abrasion.

Research done in Washington State has demonstrated the effectiveness of bioretention technologies, such as rain gardens and bioswales, which can be installed to improve the quality of stormwater. Additionally, research conducted in Oregon has shown the effectiveness of permeable pavements in improving stormwater quality.

USTMA is currently engaging with potential partners to advance practical knowledge around promising stormwater solutions, and is eager to share more about that work as those projects are formalized.

USTMA would welcome the opportunity to collaborate with Congress – as well as regulators, affected partners and interested stakeholders – to develop policies that take advantage of bioretention technologies, permeable pavements and other technologies to help mitigate stormwater impacts associated with roadways.